Thermostats

This next component, the Thermostat, is actually more of a mechanical device than an electrical one. The purpose, as the name implies, is to react in some way to temperature. Let me make a point that there are multiple types of thermostats - two of which are more mechanical than electrical - but I'll go over all three just so you understand what is going on. While they may all work slightly differently - they all work on a similar principle, as you will soon see.

- Automotive Thermostat

- Heating/AC (HVAC) Thermostat

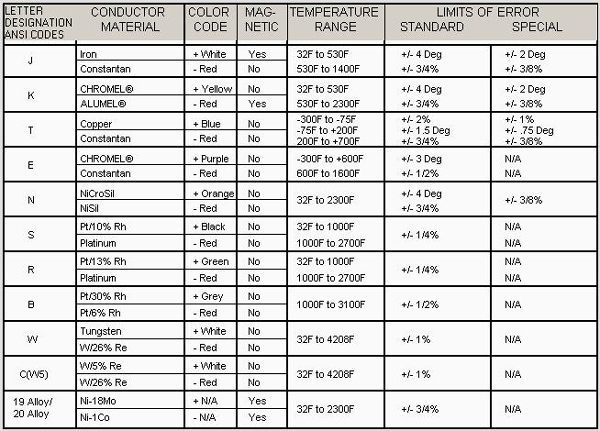

- Electrically Resistive Thermostat Finally, someone did electrical tests on that bimetal junction, (the point where the two metals were joined) and found that when it was heated - it tended to actually change not only its physical dimensions, but also its electrical resistance value. Since it is actually the electrical properties of the junction, or coupling point, of the two metals that makes the resistance change - the Electrically Resistive Thermostat has been given its own special name - the Thermocouple. Different metals were tested for various resistance changes. Some metals were found to create more linear results than others. Some were found to work over a wider range of temperatures. They were put in "type groups" based on their metallic properties. While this is not exhaustive, I'll go over some of the more common ones:

- J Type: Iron(+) / Constantan(-)

Can be used in chemically reducing atmospheres. Linear to upward to 1600° F - T Type: Copper(+) / Constantan(-)

Usable in Mildly oxidizing and usable in reducing atmospheres. Linear to upward to 750° F - K Type: Chromel(+) / Alumel(-)

Usable in some oxidizing atmospheres. Linear upward to 2300° F - E Type: Chromel(+) / Constantan(-)

Usable in Mildly oxidizing and usable in reducing atmospheres, and in vacuums. Linear to upward to 1600° F

The Automotive type Thermostat is of little use to us electrically, but should be mentioned here to rule it out. An Automotive type Thermostat is a device which physically moves due to temperature, but is completely different from the other two Thermostat devices, in that it operates in a different manner. An Automotive type Thermostat has a spring loaded valve which blocks the flow of fluid (in the case of an automobile, liquid coolant - typically Ammonium Glycol) through the system. In addition to the spring, it has a plunger (surrounded by the spring) which is filled with wax. Like most substances - the wax expands as it gets hotter, and contracts as it gets cooler. The expanding wax pushes the plunger, which pushes against the spring opening the valve, which lets cooling fluid go through.

The Automotive type Thermostat is of little use to us electrically, but should be mentioned here to rule it out. An Automotive type Thermostat is a device which physically moves due to temperature, but is completely different from the other two Thermostat devices, in that it operates in a different manner. An Automotive type Thermostat has a spring loaded valve which blocks the flow of fluid (in the case of an automobile, liquid coolant - typically Ammonium Glycol) through the system. In addition to the spring, it has a plunger (surrounded by the spring) which is filled with wax. Like most substances - the wax expands as it gets hotter, and contracts as it gets cooler. The expanding wax pushes the plunger, which pushes against the spring opening the valve, which lets cooling fluid go through.

So the basic purpose of the Automotive Thermostat is to keep the engine WARM until it reaches a certain temperature, then it lets the coolant flow through to regulate the temperature throughout the engine. This is important in colder environments to allow the engine to warm up quickly. In many (warmer) parts of the world - an engine would work fine if you completely removed the thermostat. Note: This type of thermostat does NOT work with electricity, and does NOT work on a "bimetal" principle like the other two types.

The Heating/AC type Thermostat Also works on the principle of heat causing mechanical movement, but in a different way. Much like the wax - nearly all substances and elements expand when they get hot, and contract when they get cold (water/ice being one of the few exceptions). This is also true for things like metals. However, different metals expand at different rates, because their melting points, etc differ. Gemma Frisius, in search of a more accurate timepiece, first postulated the idea of using two metals (opposing pendulums) in a clock to compensate for temperature variances as one travelled. However it was John Harrison who first bonded them together.

The Heating/AC type Thermostat Also works on the principle of heat causing mechanical movement, but in a different way. Much like the wax - nearly all substances and elements expand when they get hot, and contract when they get cold (water/ice being one of the few exceptions). This is also true for things like metals. However, different metals expand at different rates, because their melting points, etc differ. Gemma Frisius, in search of a more accurate timepiece, first postulated the idea of using two metals (opposing pendulums) in a clock to compensate for temperature variances as one travelled. However it was John Harrison who first bonded them together.

What happens if we join (say, tack-weld) two slim strips of differing metals (copper and aluminum for instance) together. They get hot at the same rate - but their expansion rates differ. One piece of metal will try to expand or "stretch" faster than the other one, but being permanently joined - it can not easily do this. The metal with the lower expansion rate will try to hold the other metal back. This will cause both metals to "bend". This is the basic theory behind any bi-metal thermostat. The two metals, when bonded together, try to expand at different rates, and cause the whole structure to bend or warp. While one is expanding, the other is holding it back.

In clocks with springs, if we take 2 different springs (one aluminum, one copper) and bond them. then as it heats up, it expands and the coil automatically unwinds. If we cool them down, they contract, and the coil tightens up. In this manner, using a bonded bimetal coil, the clockmaker can make a clock that compensates for temperature!

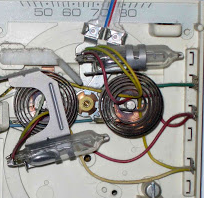

Somewhere along the way, somone found out that if they connect a switch to that spring, they can use temperature to trigger the switch. While it is perfectly possible to do so with, say, a microswitch of some kind - for the most part - it is usually done with either a ball or a mercury switch.

Somewhere along the way, somone found out that if they connect a switch to that spring, they can use temperature to trigger the switch. While it is perfectly possible to do so with, say, a microswitch of some kind - for the most part - it is usually done with either a ball or a mercury switch.

In the case of a ball switch, as the coil unwinds, the switch changes position until the ball 'falls' and makes contact. Then when the coil winds back up, the ball 'falls' in the other direction and stops making contact. Mercury switches work in the same manner - except the mercury is encapsulated and self contained. As such, the switch will never "get stuck", nor will the contacts corrode or otherwise become unusable - making a mercury switch highly reliable. In home HVAC work, mercury switch controllers used to be used extensively, but have since been replaced with either digital or ball switch controllers because of concerns of mercury poisoning. The switches were often used to control relays that turned on blowers (air handlers), heating units, and/or cooling pumps & compressors.

Another interesting implementation of this, which I've heard of but never seen, is taking one end of the coil, and instead of connecting it to a switch - connect it to a potentiometer or rheostat. By doing so, as the coil unwinds, it turns the pot varying the resistance.